Pultrusion profiles in special resins

By varying in resin, especially the chemical and physical properties of our pultrusion profiles can be manipulated. When a client has specific wishes in this area, we will look for special resins or additives to meet these wishes.

Below some examples of specific wishes that are possible:

- Deviating surface quality

- Can be glued well

- Increased fire safety (flame retardant)

- Increased chemical resistance

- Deviating colours (special profile colours)

- Higher temperature resistance / glass transition temperature(Tg)

- Comply with certain standards /certifications:

- Non-toxic, Biocompatible epoxy resins (complying with USP / FDA standards)

- Aerospace certifications

- GL classification (Germanischer Lloyd)

- Military defence standards (MIL –STD ) such as MIL R 9300 specifications

- NASA low outgassing specifications (ASTM E595 test requirements)

- Etc.

Some examples of resin types with matching specific properties and (dis)advantages:

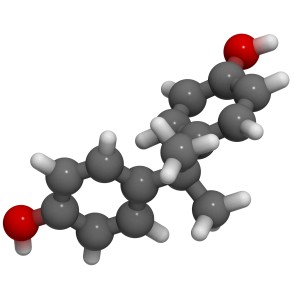

Epoxy resins – Bisphenol A / Anhydride curing

This type of resin is mainly used in high-grade structural components. They have very good mechanical and dynamic properties and enable a surface that can be glued well. The thermal and chemical properties are also excellent.

Epoxy resins – Aliphatic polyamine curing

These resins have very good physical properties and have a high chemical resistance.

Moreover, they have very favourable anti-ageing characteristics and toxicological properties. These resins are often used in food and health related applications with USP and FDA standardisations.

Bismaleimide (BMI) resins

BMI resins are very tough and are highly temperature-resistant (Tg up to 250-300 °C). The superior mechanical and thermal properties allow this resin to be applied increasingly often for the manufacture of high-grade structural composite components for the aerospace industry.

Vinylester resins

This type of resin approximates the mechanical properties of epoxy resins. The chemical resistance is also good. The most important advantage is that it can be processed relatively well and that smooth/fibre-free surfaces are possible. Disadvantages are the high shrinkage, which makes it difficult to control it retaining its shape, and also the lower temperature resistance.

« Back